Crawler self-propelled grass cutter

Remote-controlled and self-propelled high-performance mulchers share core high-efficiency configurations while offering differentiated advantages:

Shared Advantages: Equipped with a 35kW Changchai engine + hydrostatic transmission system for stable and reliable performance; capable of operating on slopes ≤55° with automatic correction and tilt protection; 27 tungsten steel blades efficiently shred vegetation ≤100mm at 2500 RPM; tool change time <10 minutes; integrated multi-level safety systems including real-time status monitoring, emergency braking, automatic shutdown, and cooling and dust removal systems.

Product Details

Product Introduction

The Crawler Self-Propelled Mulcher is a purpose-built, high-efficiency machine engineered for demanding vegetation management tasks. This robust mulcher is powered by a reliable 35kW Changchai direct-injection diesel engine, paired with an advanced hydrostatic transmission featuring a piston and gear pump combination. This system delivers precise, bi-directional speed control from 0-100%, a working speed of 0-4 km/h, and a transport speed of up to 10.2 km/h. Its core mulching performance is driven by 27 tungsten steel blades rotating at 2500 RPM, capable of shredding vegetation up to 100mm in diameter across a 1200mm working width. Engineered for extreme terrain, it operates reliably on slopes up to 55° with built-in tilt protection and automatic correction (straight-line deviation of just 0.3%). Its optimized hydraulic and engine systems allow for stable operation at tilt angles up to 60°, and even up to 80° in any direction for the hydraulic system specifically. The machine's superior traction and adaptability come from its high-tooth rubber tracks, which provide twice the grip of standard market tracks, a 500mm wading depth

Product Details

Fitted with premium hydraulic hoses from Continental (Germany) or Yokohama (Japan), ensuring long-lasting durability and dependable performance. | Fitted with heavy-duty rubber tracks featuring reinforced anti-slip treads for enhanced traction and stable mobility. | ||

The dual-direction fan with integrated cooling maintains ideal operating temperatures while automatically clearing dust for continuous efficiency. |

Technical Parameters

Parameter | Specification | Parameter | Specification |

Model | HYZH-40 | Pressure | 250bar |

Engine Brand | Changchai | Headlight | LED |

Fuel | Diesel | Tool Rotation Speed | 2500rpm |

Fuel Tank Capacity | 28L | Tool Rotation Direction | Forward/Reverse (Bi-directional 0-100% stepless adjustable) |

Torque | 105.5Nm | Attachment Front Cover Control | Remote control |

Fuel Injection Method | Direct injection | Tool Material | Tungsten steel |

Rated Power | 35Kw | Working Width | 1200mm |

Transmission System | Hydrostatic precision control | Number of Tools | 27 pieces |

Cooling System | Oil-air hybrid cooling | Crushing Diameter | 100mm |

Vertical Obstacle Height | 500mm | Forearm Lifting Range | -200mm to +500mm |

Wading Depth | 500mm | Slope Capacity | Suitable for 55° slope operation |

Departure Angle | 30° | Dimensions | 3230mm × 1450mm × 1420mm |

Straight-line Deviation | 0.3% | Machine Weight | 1840kg |

Topsoil Turning Depth | 20mm | Ground Clearance | 170mm |

Remote Control Range | >150m | Terrain Adaptability | Yes (adapts to ±10° terrain undulation) |

Allowed Tilt Angle | 60° in any direction (after engine optimization) | Steering System | Skid steering, supporting in-place turning |

Hydraulic Pump | Piston pump + Gear pump | Allowed System Tilt | ≥80° in any direction (after hydraulic system optimization) |

Drive Motor | High-torque motor | Speed Control | Working speed: 0-4 km/h (forward/reverse); Transfer speed: 0-10.2 km/h (forward/reverse) |

Hydraulic Tank Capacity | 26L (40L total system capacity) | Parking System | Remote-controlled parking brake |

Hydraulic Flow Rate | 84L/min | Track Type (Standard) | High-tooth rubber track (suitable for 55° slope operation). The tooth height of the special working condition rubber track is twice that of ordinary/common tracks on the market, achieving strong grip, friction, and adaptability to various terrains |

Frequency | 2.4G | Battery | 2 built-in rechargeable lithium batteries per unit, supporting self-charging |

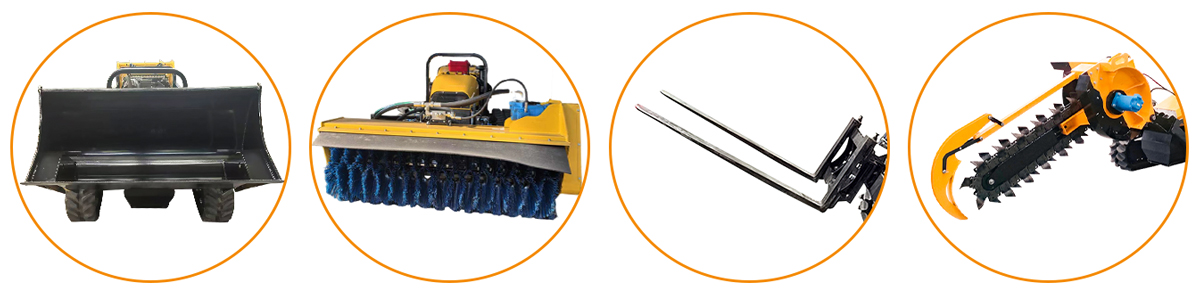

Optional Attachments

Application Scenarios

The Self-Propelled Mulcher for Sale is engineered to master the most demanding outdoor environments, delivering professional-grade performance across a spectrum of heavy-duty applications:

Forestry & Land Clearing: Designed for intensive tasks, its 35kW high-torque diesel engine and 27 tungsten steel blades (2500 RPM) efficiently shred undergrowth, brush, and small trees up to 100mm in diameter. The hydrostatic transmission and high-tooth rubber tracks provide the traction and control needed for powerful, continuous operation in dense woodland.

Steep Slope & Mountainous Terrain: With engineered stability for operations on slopes up to 55° and systems optimized for tilt angles up to 60° (80° hydraulically), it ensures safe and effective performance on challenging inclines. The automatic slope correction minimizes lateral deviation, maintaining precision on uneven hillsides.

Infrastructure & Right-of-Way Maintenance: Its compact design (3230mm length) combined with skid-steer in-place turning offers exceptional maneuverability for maintaining roadsides, power lines, and pipeline corridors. The ability to adapt to ±10° ground undulations and wade through 500mm depths makes it ideal for rough, variable terrain.

Land Reclamation & Site Preparation: A robust tool for transforming overgrown or rugged areas into usable land for agriculture or construction. The high working speed (0-4 km/h) and efficient mulching action clear vegetation rapidly, preparing the topsoil with minimal disturbance.

Orchard & Vineyard Management: Provides a stable, precise solution for managing vegetation between tree rows and maintaining clean aisles, helping to reduce pest habitats and fire hazards without compromising crop safety.

Wetland & Sensitive Area Restoration: The low ground pressure from its track system and significant wading capability allow it to operate effectively in soft or wet conditions, supporting projects aimed at invasive species removal and habitat restoration with reduced environmental impact.

Packaging & Shipping

To ensure the Best Self-propelled Mulcher arrives in optimal condition and is ready for immediate operation, we implement a systematic, multi-tiered professional packaging protocol. This approach guarantees that your equipment is delivered intact and without damage.

Precision Inner-layer Protection: The entire machine is first fully wrapped in high-toughness, transparent film. This creates an initial barrier against dust, moisture, and minor abrasions, preserving the factory-fresh state.

Sturdy Palletized Base: The unit is professionally secured onto a heavy-duty, custom-made wooden pallet. This design not only facilitates safe hoisting and forklift handling but also effectively disperses vibrations and pressure during transit, complying with standardized logistics procedures for ports and worksites.

Reinforced Outer Crate Structure: For long-distance or international shipments, the palletized equipment is enclosed within a sealed outer crate constructed from reinforced timber. The strengthened crate structure is engineered to withstand impacts, stacking pressures, and other complex stresses inherent in long-haul sea freight or multimodal transportation.

Additional Safety Measures: Throughout the packaging process, meticulous attention is given to detail. Critical components (such as hydraulic line fittings and LED lights) receive extra cushioning protection. Furthermore, the equipment is secured in a locked and braked position inside the crate to prevent any internal movement.

Through this rigorous, multi-layered protective system, we are committed to delivering every high-performance machine to your location safely and punctually, ensuring the smooth commencement of your project.

Company Profile

Qingdao Huaying Intelligent Equipment Co., Ltd., a key member of the Shandong Hongchuan Machinery Group, specializes in the R&D, manufacturing, and global distribution of innovative small-to-medium intelligent machinery solutions. Headquartered in Jining, China, we are committed to empowering industries such as forestry management, ecological restoration, roadside maintenance, and agricultural land clearing with high-efficiency, user-friendly equipment.

As part of our product ecosystem, we offer specialized Remote Forestry Attachments designed for demanding terrain and hazardous operational environments. These remote-controlled systems are engineered to integrate seamlessly with our core machinery platforms, providing operators with a safe and effective solution for vegetation management in challenging conditions. This enables precise mulching, clearing, and land preparation without exposing personnel to direct risks, particularly on steep slopes or in unstable ground areas.

Driven by a culture of technical excellence and customer-focused innovation, we deliver reliable, adaptable equipment tailored to practical field requirements, helping professionals worldwide enhance productivity and operational safety.

Why Choose Us?

Highly Efficient and Reliable Power & Mulching System

Equipped with a 35kW Changchai direct-injection diesel engine that delivers a robust torque of 105.5 Nm, ensuring ample and dependable power.

Features 27 tungsten steel blades operating at a high speed of 2500 RPM, capable of efficiently shredding various types of vegetation with diameters up to 100mm.

The hydrostatic transmission system (combining piston and gear pumps) enables stepless speed control from 0-100%, with a working speed of 0-4 km/h and a maximum transport speed of 10.2 km/h, ensuring precise operation and卓越的效率 (exceptional efficiency).

Outstanding Mobility and Operational Convenience

Utilizes a skid-steer system that allows for in-place turning, providing exceptional maneuverability in confined spaces.

The remote-control model offers an operating range exceeding 150 meters and is equipped with a dual lithium battery system supporting self-charging, ensuring safety and convenience during prolonged operation.

Tool change time is under 10 minutes, significantly enhancing equipment utilization and operational flexibility.

Comprehensive Safety and Durability DesignIntegrates multiple safety protections including real-time status monitoring, emergency braking, and automatic shutdown.

Fitted with an oil-air hybrid cooling system and a dust removal device to ensure the stable operation of key components under prolonged, high-load conditions.

Key structural features, such as a forearm lifting range of -200mm to +500mm, a ground clearance of 170mm, and a vertical obstacle clearance of 500mm, effectively protect the main unit and extend its service life.

Remote-controlled parking brake provides additional operational safety assurance.

Leave your messages