Remote Controlled Mower For Hills

Slope-Ready Design: The remote controlled mower for hills works on slopes up to 55° with advanced lubrication, ideal for hilly terrain.

Stable Tracks: Anti-slip tracks plus oil pan ensure the remote controlled mower for hills operates safely on steep slopes.

Remote Control: Wireless operation keeps operators safe—critical for the remote controlled mower for hills’ hill work.

Product Introduction

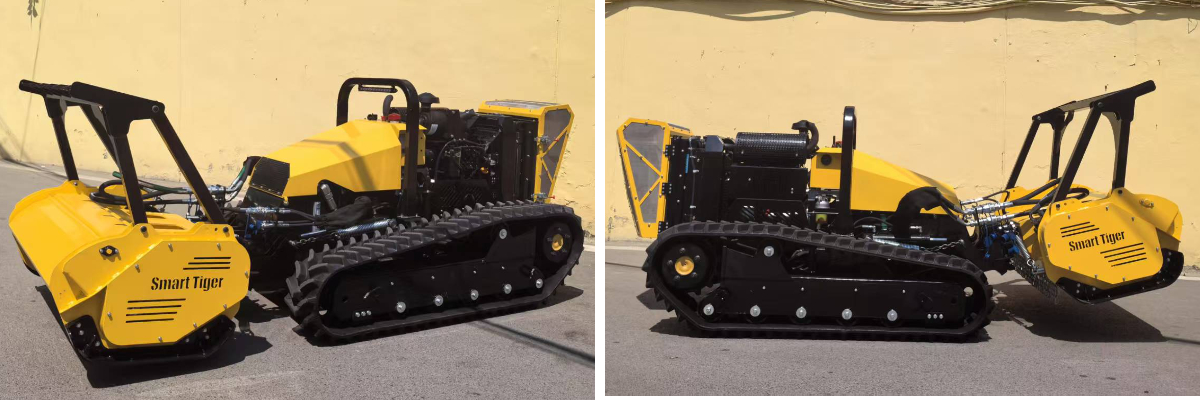

The Hydraulic Remote Controlled Mower for Hills and Remote Lawn Mower For Hills are durable, high-performance machines engineered for safe, efficient vegetation management on hilly terrain.

Both models are powered by a YANMAR diesel engine and sophisticated hydraulic system, enabling precise control over movement, cutting attachments, and track operation. Their reinforced heightened-tooth rubber tracks ensure stability on slopes up to 55°—a core hill-use advantage—while adjustable rotor speeds and versatile tools efficiently handle grass, shrubs, and 100mm-diameter small branches.

Equipped with full safety protections and a >150m-range remote control, they excel at maintaining lawns, orchards, roadside greenery, and steep/challenging hilly terrains.

Product Details

Equipped with Continental (Germany) or Yokohama (Japan) hydraulic hoses for durability and reliability. | Fitted with heavy-duty rubber tracks featuring reinforced anti-slip treads for enhanced traction and stable mobility. | ||

Dual-direction fan system with integrated cooling ensures optimal temperature control and automatic dust removal. | Remote-controlled mulching head with stepless speed adjustment and seamless forward/reverse rotation switching. |

Technical Parameters

Parameter | Specification | Parameter | Specification |

Model | HYZH-40 | Pressure | 250bar |

Engine Brand | YANMAR | Headlight | LED |

Fuel | Diesel | Tool Rotation Speed | 2500rpm |

Fuel Tank Capacity | 28L | Tool Rotation Direction | Forward and reverse (bidirectional 0-100% stepless adjustable) |

Torque | 107.1Nm | Control of Attachment Front Cover Opening/Closing | Remote control |

Fuel Injection Method | Direct injection | Tool Material | Tungsten steel |

Rated Power | 28.2Kw | Working Width | 1200mm |

Transmission Mode | Hydrostatic precision control | Number of Tools | 27 |

Cooling Method | Oil-air hybrid cooling | Crushing Diameter | 100mm |

Vertical Obstacle Crossing Height | 500mm | Forearm Lifting Height | -200mm to 500mm |

Wading Depth | 500mm | Supported Slope | Meets working conditions with a slope angle of 55° |

Departure Angle | 30° | Dimensions | 3230mm × 1450mm × 1420mm |

Straight-line Deviation Angle | 0.3% | Self-weight | 1840kg |

Topsoil Backfilling Depth | 20mm | Maximum Traction Force | 25KN |

Working Distance of Remote Control System | >150m | Ground Clearance | 170mm |

Allowed Operating Inclination Angle | 60° in any direction (after engine optimization) | Attachment Terrain Matching | Yes (matches terrain undulations within ±10°) |

Hydraulic Pump | Piston pump + gear pump | Steering | Skid steering, supporting in-place steering |

Drive Motor | High-torque motor | System Allowed Operating Inclination Angle | ≥80° in any direction (after hydraulic system optimization) |

Hydraulic Tank Capacity | 26L (40L in the system) | Hydraulic Flow of Reclamation Attachment | 84L/min |

Stepless Speed Control | Working speed: forward/reverse 0-4 Km/h; Transfer speed: forward/reverse 0-10.2 Km/h | Parking Mode | Remote control. The parking switch ensures stable parking of the equipment. The parking knob enables on-site parking and electronic handbrake function, effectively ensuring safety, preventing sliding, and avoiding safety accidents caused by misoperation. |

Rubber Track (Standard) | High-tooth rubber track (supports 55° slope working conditions). Special working condition rubber track with teeth twice as high as ordinary/common tracks on the market, achieving strong grip, friction, and adaptability to various terrains | Proportional Joystick | Supports joystick direction switching for convenient operation when driving with the front or rear of the machine forward. Direction switching (forward/reverse) can be realized via the knob switch, which is more efficient without the need for U-turn. |

Frequency | 2.4G | Battery | 2 built-in rechargeable lithium batteries per unit, supporting self-charging |

Optional Attachments

Application Scenarios

The Remote Controlled Mower for Hills and Remote Control Lawn Mower For Hills (both optimized for sloped terrain) excel in vegetation management across key scenarios:

Urban Greening: Maintain parks, greenways, and roadside slopes—ideal for sloped urban green spaces.

River & Flood Dike Maintenance: Remove vegetation to protect embankments and ensure flood safety on sloped dikes.

Highway & Railway Slope Clearing: Support transport corridor slope management, handling sloped sections safely.

Agricultural Slope Maintenance: Clear farmland/orchard edges on sloped terrain without crop damage.

Mountain & Forest Land Management: Handle grass cutting and land reclamation in rugged, sloped mountain/forest areas.

Power Line & Hazard Zone Control: Enable safe vegetation clearing in restricted/dangerous sloped areas, keeping operators risk-free.

Packaging & Shipping

To guarantee every remote controlled mower for hills and Remote Mower For Hills reaches its destination in perfect working order, we follow a meticulous multi-layered packaging process:

Dust & Moisture Protection: Each unit is tightly wrapped in transparent film, guarding against dust, moisture, and minor surface damage during transit.

Palletized Base: Units are mounted on durable wooden pallets, enabling safe forklift operations and smooth loading/unloading at ports, warehouses, or job sites.

Reinforced Crates: For long-distance/international shipping, palletized units are enclosed in heavy-duty wooden crates, protecting against impacts, compression, and transport stresses.

This ensures both models arrive in perfect condition, fully protected, and ready for immediate operation.

Company Profile

Qingdao Huaying Intelligent Equipment Co., Ltd.—a subsidiary of Shandong Hongchuan Machinery Manufacturing Co., Ltd.—focuses on R&D, production, and sales of small-to-medium-sized intelligent machinery, with remote controlled mower for hills and Remote Mower For Hills as key offerings.

Leveraging strong technical capabilities and a robust regional industrial base, we provide efficient, versatile, easy-to-use solutions (including the two hill mower models) for gardens, roads, orchards, and sloped-terrain applications.

Committed to quality and innovation, our equipment (such as the remote controlled mower for hills and Remote Mower For Hills) is designed to boost productivity, support sustainability, and deliver reliable real-world performance.

Why Choose Us?

At Qingdao Huaying Intelligent Equipment, we combine deep industry expertise and advanced engineering to design field-ready machines—including the Remote Forestry Mulcher, remote controlled mower for hills, and Remote Mower For Hills. The mulcher suits rugged terrains/steep slopes; the two hill mowers excel at safe, efficient vegetation management on hilly terrain—all prioritize performance and safety.

Backed by reliable manufacturing, continuous innovation, and field insight, our equipment delivers:

Dual safety systems + automatic shutdown for stable operation on extreme inclines;

High-efficiency mulching (mulcher) / hill-focused cutting (hill mowers) with strong landscape adaptability;

Quick tool-free attachment changes to avoid workflow interruptions;

Smart diagnostics + real-time monitoring for hassle-free use;

Low-maintenance, transport-ready design to minimize downtime.