Product Introduction

Remote-Operated Tracked Mower and Zero-Turn Tracked Mower (equipped with tracks for enhanced maneuverability) are high-performance vegetation management machines designed for challenging terrain and steep slopes.

Both models feature:

Tilt sensors, slope-over alarms, and automatic shutdown (maximizing operational safety);

Advanced hydrostatic drive with slope correction (stable performance on inclines up to 55°);

Integrated oil-water cooling system with reversible fan (ensuring efficient operation in harsh conditions);

Fully wireless remote operation (enabling easy control of engine functions, lighting, horn, and attachments);

Quick-change hydraulic couplers, high-strength tungsten steel blades, and real-time monitoring (water/oil temperature, oil level, RPM, and blockage alerts).

The Remote-Controlled Tracked Mower excels in forestry, land clearing, and slope maintenance applications; the Zero-Turn Tracked Mower adds superior agility for precise trimming in complex landscapes. Both deliver efficient, reliable, and safe vegetation management performance.

Product Details

Equipped with Continental (Germany) or Yokohama (Japan) hydraulic hoses for durability and reliability. | Fitted with heavy-duty rubber tracks featuring reinforced anti-slip treads for enhanced traction and stable mobility. | ||

Dual-direction fan system with integrated cooling ensures optimal temperature control and automatic dust removal. | Remote-controlled mulching head with stepless speed adjustment and seamless forward/reverse rotation switching. |

Technical Parameters

Parameter | Specification | Parameter | Specification |

Model | HYZH-40 | Pressure | 250bar |

Engine Brand | YANMAR | Headlight | LED |

Fuel | Diesel | Tool Rotation Speed | 2500rpm |

Fuel Tank Capacity | 28L | Tool Rotation Direction | Forward and reverse (bidirectional 0-100% stepless adjustable) |

Torque | 107.1Nm | Control of Attachment Front Cover Opening/Closing | Remote control |

Fuel Injection Method | Direct injection | Tool Material | Tungsten steel |

Rated Power | 28.2Kw | Working Width | 1200mm |

Transmission Mode | Hydrostatic precision control | Number of Tools | 27 |

Cooling Method | Oil-air hybrid cooling | Crushing Diameter | 100mm |

Vertical Obstacle Crossing Height | 500mm | Forearm Lifting Height | -200mm to 500mm |

Wading Depth | 500mm | Supported Slope | Meets working conditions with a slope angle of 55° |

Departure Angle | 30° | Dimensions | 3230mm × 1450mm × 1420mm |

Straight-line Deviation Angle | 0.3% | Self-weight | 1840kg |

Topsoil Backfilling Depth | 20mm | Maximum Traction Force | 25KN |

Working Distance of Remote Control System | >150m | Ground Clearance | 170mm |

Allowed Operating Inclination Angle | 60° in any direction (after engine optimization) | Attachment Terrain Matching | Yes (matches terrain undulations within ±10°) |

Hydraulic Pump | Piston pump + gear pump | Steering | Skid steering, supporting in-place steering |

Drive Motor | High-torque motor | System Allowed Operating Inclination Angle | ≥80° in any direction (after hydraulic system optimization) |

Hydraulic Tank Capacity | 26L (40L in the system) | Hydraulic Flow of Reclamation Attachment | 84L/min |

Stepless Speed Control | Working speed: forward/reverse 0-4 Km/h; Transfer speed: forward/reverse 0-10.2 Km/h | Parking Mode | Remote control. The parking switch ensures stable parking of the equipment. The parking knob enables on-site parking and electronic handbrake function, effectively ensuring safety, preventing sliding, and avoiding safety accidents caused by misoperation. |

Rubber Track (Standard) | High-tooth rubber track (supports 55° slope working conditions). Special working condition rubber track with teeth twice as high as ordinary/common tracks on the market, achieving strong grip, friction, and adaptability to various terrains | Proportional Joystick | Supports joystick direction switching for convenient operation when driving with the front or rear of the machine forward. Direction switching (forward/reverse) can be realized via the knob switch, which is more efficient without the need for U-turn. |

Frequency | 2.4G | Battery | 2 built-in rechargeable lithium batteries per unit, supporting self-charging |

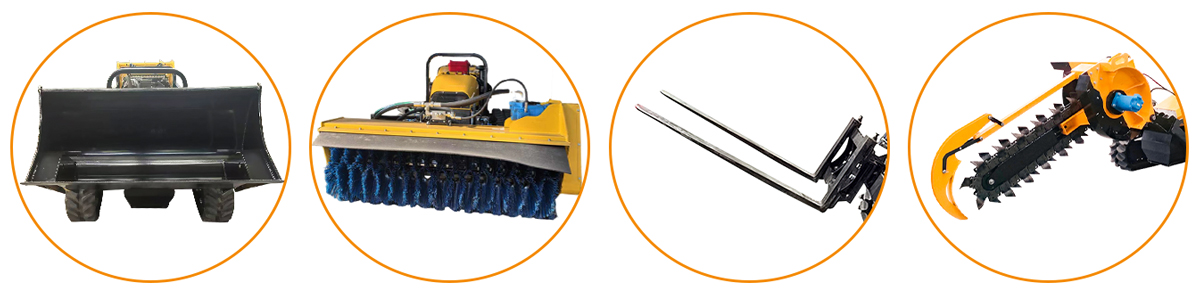

Optional Attachments

Application Scenarios

Remote-Operated Tracked Mower (for heavy-duty terrain tasks) and the Wireless-Controlled Track Mower (versatile track-equipped model) are both engineered for a variety of demanding outdoor environments, with core use cases including:

Forestry: Both handle shrub coppicing, understory combustible cleaning, and firebreak establishment;

Grasslands: Both excel at dead grass cleaning and firebreak setup;

Roads: Both support highway green belt pruning, slope/municipal park lawn care, and road snow removal;

Dykes: Both enable dyke weed/shrub cleaning and timely detection of potential safety hazards to prevent accidents.

The Remote-Controlled Tracked Mower focuses on high-intensity, steep-terrain operations, while the Track Mower offers flexible adaptability for daily vegetation management across mixed outdoor scenarios.

Packaging & Shipping

Professional Packaging Solution: Remote-Controlled Forestry Mulcher & Wireless Tool Carrier

To ensure the Remote-Controlled Forestry Mulcher and the Wireless Tool Carrier (designed for multi-attachment mounting) arrive in perfect condition, we implement a multi-layered packaging system:

Dustproof & Moisture-Resistant Wrapping – Both units are sealed in high-transparency plastic film, forming a tight barrier against dust, moisture, and minor scratches to protect exteriors and key components.

Palletized Base for Easy Handling – Each machine is securely fastened to heavy-duty wooden pallets with anti-slip fasteners, enabling smooth forklift loading/unloading at ports and warehouses, minimizing tilting and shifting.

Heavy-Duty Reinforced Crates – For long-distance and international shipments, both are enclosed in reinforced wooden crates made of thickened lumber with strengthened corners, offering robust protection against impacts, compression, and transit hazards to preserve structural integrity.

This comprehensive packaging solution ensures all equipment arrives fully protected, damage-free, and ready for immediate deployment.

Company Profile

Professional Manufacturer of Intelligent Remote-Operated Forestry Machinery

As a distinguished subsidiary of Shandong Hongchuan Machinery, we are a leading enterprise specializing in the research and development, manufacturing, and sales of small-to-medium intelligent equipment, including the specialized Remote-Control Forestry Mulcher.

Headquartered in Jining—a city renowned for its industrial heritage and innovation—we provide efficient, reliable, and user-friendly machinery solutions for landscaping, road maintenance, orchard management, land clearing, and environmental governance.

With strong technical expertise, advanced production capabilities, and decades of industry experience, we design equipment to tackle real-world challenges. Our Remote-Control Forestry Mulcher, for example, is engineered for safe and efficient operation on steep and complex terrain.

Committed to continuous innovation, all our products—including the Remote-Control Forestry Mulcher—are built with durability, adaptability, and intelligent functionality, helping global clients enhance productivity, safety, and operational efficiency.

By integrating cutting-edge technology with practical engineering, we have become a trusted partner for customers seeking intelligent and reliable machinery solutions worldwide.

Why Choose Us?

At Qingdao Huaying Intelligent Equipment, we combine deep industry knowledge with advanced engineering to design machines built for the most demanding environments. Our Remote-Controlled Forestry Mulcher is specially engineered to handle rugged terrain, steep slopes, and heavy-duty tasks—all via full wireless remote operation, delivering superior safety and productivity for operators.

Built on reliable manufacturing principles, continuous innovation, and proven field performance, this mulcher is equipped with the following key advantages:

Dual Safety Protection with Auto Shutdown: Offers secure performance on extreme slopes, delivering dual-layer safety during incline operations.

High-Strength Tungsten Blades: Ensures efficient mulching across various vegetation types—from thick shrubs to dense undergrowth—with long-lasting sharpness and durability.

Rapid Attachment Switching: Allows quick interchange of working tools to adapt to different tasks such as brush clearing and vegetation shredding, minimizing job changeover time.

Intelligent Monitoring & Diagnostics: Tracks critical operating data in real time—including temperature, pressure, and blade condition—and provides smart alerts for reliable operation and preventive maintenance.

Logistics-Ready Design & Easy Upkeep: Features a compact and transport-optimized structure for hassle-free shipping, alongside simplified maintenance to reduce downtime and sustain smooth performance.

Designed for forestry, land clearing, slope maintenance, and environmental management, our Remote-Controlled Forestry Mulcher delivers a powerful, adaptable, and user-focused solution—backed by competitive remote control mulcher pricing tailored to international market needs.