Tracked Forestry Mulcher

Tracked Forestry Mulcher - Smartiger The Smartiger Tracked Forestry Mulcher is a high-performance, robust piece of equipment engineered for efficient and reliable vegetation management in demanding forestry, land clearing, and slope maintenance applications. Tailored to meet the stringent operational standards of international markets, it integrates advanced powertrain, hydraulic, and control technologies to deliver exceptional productivity even in harsh working conditions. Engine Configuration Powered by a YANMAR 3-cylinder, 4-cycle inline water-cooled diesel engine that complies with the European III emission standard, this mulcher ensures eco-friendly operation without compromising power output.

Product Introduction

The Forestry Mulcher for Sale (Tracked Forestry Mulcher) is a robust, versatile solution for demanding vegetation management:

Power & Compliance: 38.3 HP YANMAR 3-cylinder diesel engine (meets European Stage III emission standards).

55° Slope Capacity: Works safely on steep terrain (any direction) where conventional equipment fails.

Efficient Mulching & Control: Independent closed-circuit flail system (consistent performance); 150m remote control with proportional joysticks (max safety/precision).

Compact yet powerful, this model (Smartiger) is ideal for forestry, landscaping, and roadside maintenance

Hydraulic System

The mulcher features a high-performance hydraulic system designed for precise and responsive operation. Its hydraulic configuration includes 3-tandem piston pumps + 2 gear pumps from Bondioli & Pavesi, ensuring stable oil supply and strong power transmission. The driving system is equipped with Poclain high-torque motors to deliver superior traction, while the flail mower is driven by a Danfoss high-speed motor for efficient mulching performance.

The hydraulic circuit is divided into three independent modules for optimized functionality:

Independent flail head circuit: Adopts a closed-circuit piston design for consistent mulching speed and cutting force.

Independent track drive circuit: Configured with 2 sets of closed-circuit piston systems to ensure reliable track operation and excellent slope adaptability.

Independent motions circuit: Uses an open-circuit gear design to support flexible and precise control of the machine’s movement and working actions.

Track System

Fitted with heightened teeth rubber tracks, the Smartiger mulcher excels in terrain adaptability, enabling safe and stable operation on slopes with a maximum working angle of 55°. The rubber track design minimizes ground damage, making it suitable for operation in sensitive areas such as ecological reserves and landscape maintenance sites.

Remote Control System

For operator safety and operational flexibility, the mulcher is equipped with a professional remote control system with the following features:

Working range: Over 150 meters, allowing operators to control the machine from a safe distance away from hazardous working zones.

Frequency: 2.4G wireless transmission, ensuring stable signal and anti-interference performance.

Battery: Interchangeable and rechargeable battery packs, with two units provided per machine; one can be charged on the machine while the other is in use, ensuring uninterrupted operation.

Proportional joysticks: Standard configuration for precise, smooth control of all machine functions.

Dimensions and Weight

Overall width: 1500 mm / 2900 mm (with flail mower installed, dual-width specifications to meet different working space requirements)

Overall height: 1300 mm (with flail mower installed)

Machine weight: 1250 Kg

Mulcher attachment weight: 380 Kg

Performance Highlights

The Smartiger Tracked Forestry Mulcher demonstrates outstanding slope operation capability, supporting work on slopes up to 55° in any direction. To ensure operational safety, a built-in safety protection system triggers an alarm when the slope angle reaches 50°, and automatically shuts down the machine when the angle hits 55°, effectively preventing rollover risks.

Product Details

Equipped with Continental (Germany) or Yokohama (Japan) hydraulic hoses for durability and reliability. | Fitted with heavy-duty rubber tracks featuring reinforced anti-slip treads for enhanced traction and stable mobility. | ||

Dual-direction fan system with integrated cooling ensures optimal temperature control and automatic dust removal. | Remote-controlled mulching head with stepless speed adjustment and seamless forward/reverse rotation switching. |

Technical Parameters

Model | Smartiger | |

| ENGINE | ||

Maker | YANMAR 3-cylinder(European III emission standard) | |

Type | 4-cycle, Inline, Water-cooled Diesel | |

Fuel tank capacity | 28 litres | |

Gross output | 28.2Kw (38.3Hp) @2600rpm | |

Self-cleaning(optional) | Standard manual and automatic (optional) | |

HYDRAULICS | ||

Pumps | 3-tandem piston pump + 2 gear pump | (Bondioli & Pavesi) |

Driving motors | High torque motor | (Poclain) |

Flail mower motor | High speed motor | (Danfoss) |

Independent flail head circuit | Closed circuit piston | |

Independent track drive circuit | 2x closed circuit piston | |

Independent motions circuit | Opend circuit gear | |

TRACKS | ||

Rubber | Hieghtened teeth rubber track (max working angle 55°) | |

REMOTE CONTROL | ||

Working range | >150m | |

Frequency | 2.4G | |

Battery | Interchageable, rechargeable | |

Two with each unit charge on machine | ||

Propotional Joysticks | Standard | |

DIMENSIONS | ||

Overall width (with flail mower) | 1500mm | |

Overall width (with flail mower) | 2900mm | |

Overall height (with flail mower) | 1300mm | |

WEIGHT | ||

Smartiger | 1250Kg | |

Mulcher attachment | 380kgs | |

PERFORMANCE | ||

Gradient | Working on slopes up to 55° in any direction | |

(alarm at 50° and automatic shut-off at 55°) | ||

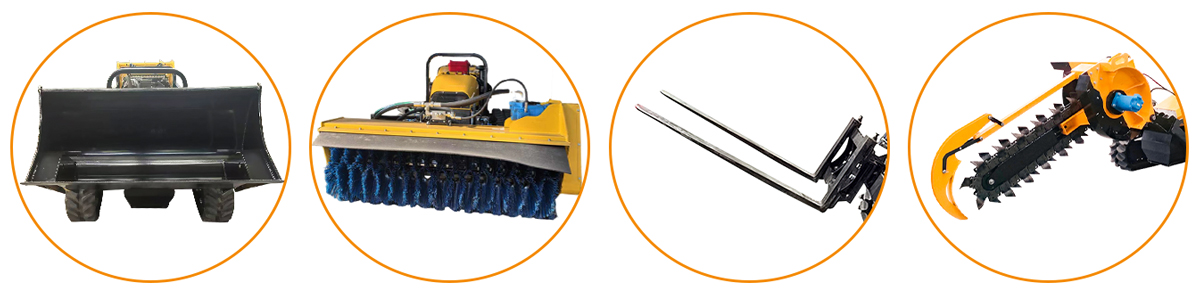

Optional Attachments

Application Scenarios

Forestry Mulcher for Sale: Robust Tracked Models for Extreme Working Conditions Our tracked forestry mulchers and forestry shredders are purpose-built for high-intensity, high-risk operational environments where uncompromised safety, superior stability, and top-tier efficiency are non-negotiable. Engineered to excel in challenging scenarios that conventional equipment fails to tackle, these machines deliver reliable performance across a diverse range of critical applications: 1. Photovoltaic Power Plant Vegetation ManagementOur tracked forestry mulcher provides targeted vegetation control around solar panel arrays. With its advanced remote-control operation system, operators can manage overgrown plants from a safe distance, eliminating the risk of accidental damage to panels and ensuring maximum personal safety during operation. 2. Steep Slope MaintenanceBoasting a maximum working angle of 55° in any direction, the tracked forestry mulcher is designed to navigate and operate safely on ultra-steep inclines. Equipped with a built-in safety mechanism, it triggers an alarm at a 50° slope angle and automatically shuts down at 55° to prevent rollover incidents, ensuring secure operation even in the most precarious terrain. 3. Mountainous Terrain ClearingFeaturing heightened-teeth rubber tracks and a high-torque hydraulic drive system, the machine delivers consistent and reliable performance in rugged, uneven mountainous landscapes. Its robust track design enhances traction and minimizes ground disturbance, making it ideal for vegetation removal and land tidying in hard-to-reach mountain areas. 4. Wildfire Prevention & Firebreak CreationBoth tracked forestry mulchers and shredders are highly efficient tools for rapid vegetation clearing, enabling the quick establishment of firebreaks. By removing combustible plants in a timely manner, these machines effectively halt the spread of wildfires, protecting forest resources, farmlands, and residential areas from fire threats. 5. Grassland & Pasture MaintenanceDesigned to maintain open grassland and pasture areas, these machines cut and shred overgrown vegetation while preserving soil integrity. The rubber track system reduces soil compaction, and the precision mulching function ensures uniform vegetation coverage, promoting healthy grass growth and improving pasture quality for livestock grazing.

Packaging & Shipping

Forestry Shredder & Tracked Forestry Mulcher: Professional Packaging for Secure Transit

To guarantee that our Forestry Shredder, Tracked Forestry Mulcher, and Remote Control Brush Cutter reach our global clients in factory-fresh, fully operational condition, we have implemented a rigorous, tiered packaging protocol tailored to withstand the rigors of domestic and international logistics:

Industrial-Grade Dustproof & Moisture-Proof Sealing

Every individual machine component and finished unit is wrapped in high-tensile transparent plastic film, which is heat-sealed to form an airtight barrier. This wrapping effectively fends off dust accumulation, moisture infiltration, and minor scratches during the initial warehousing and short-haul transfer stages, preserving the integrity of the equipment’s surface and precision parts.

Heavy-Duty Palletization with Stabilization

All wrapped units are firmly fastened onto reinforced wooden pallets using heavy-gauge steel strapping and anti-slip padding. This palletized base not only facilitates seamless handling by forklifts and cargo lifts at ports, warehouses, and job sites but also prevents shifting or tilting during the loading and unloading process, eliminating the risk of internal component damage caused by collision.

Custom Reinforced Wooden Crating for Overseas Shipments

For long-distance cross-border deliveries, palletized Forestry Shredder, Tracked Forestry Mulcher, and Remote Control Brush Cutter units are encased in custom-built heavy-duty wooden crates. These crates are constructed from high-density lumber and reinforced with additional bracing at key stress points, providing exceptional resistance to impact, compression, and jostling throughout ocean or land transportation.

Company Profile

Qingdao Huaying Intelligent Equipment Co., Ltd. Qingdao Huaying Intelligent Equipment Co., Ltd., a wholly-owned subsidiary of Shandong Hongchuan Machinery Manufacturing Co., Ltd., is a dedicated manufacturer focusing on the research and development, production, and global distribution of small and medium-sized intelligent machinery. Our product portfolio encompasses a wide range of high-performance equipment, with the Remote Control Brush Cutter being one of our flagship offerings, alongside specialized gear for garden maintenance, road upkeep, orchard management, and beyond. Endowed with robust technical R&D capabilities and leveraging the prominent industrial cluster advantages of our region, we craft equipment solutions that are defined by high efficiency, strong environmental adaptability, and intuitive user operation. We adhere to a core philosophy centered on uncompromising quality and continuous technological innovation, ensuring that every piece of machinery we produce is engineered to boost on-site operational productivity, promote sustainable working practices, and minimize operational complexity for end users in practical scenarios. Guided by customer-centric principles, we strive to deliver tailored, reliable equipment that meets the diverse demands of global clients across different application fields.

Why Choose Us?

Qingdao Huaying Intelligent Equipment Co., Ltd. At Qingdao Huaying Intelligent Equipment, we integrate profound industry expertise with cutting-edge engineering techniques to develop heavy-duty machinery that delivers exceptional performance in the most demanding real-world operational settings. Our Remote-Controlled Tracked Forestry Mulcher is specifically engineered to conquer rugged terrains, ultra-steep slopes, and heavy-duty workloads, with its full-function remote control system serving as a cornerstone to ensure unrivaled operator safety and operational efficiency. Rooted in our core commitments to reliable manufacturing, relentless technological innovation, and in-depth understanding of on-site operational requirements, this machine is equipped with a suite of competitive features: • Dual-slope safety protection system: Triggers a pre-alarm when working angles approach risky thresholds and initiates automatic shutdown at the maximum safe slope limit, ensuring foolproof operation on inclines of any gradient. • High-efficiency tungsten steel flail blade system: Boasts extraordinary adaptability to diverse terrain types, enabling efficient mulching of thick brush, small saplings, and dense undergrowth with consistent cutting performance. • Tool-free quick attachment swapping mechanism: Allows operators to switch between mulching heads and other functional attachments in minutes, facilitating seamless transition between multiple tasks without additional tools. • Intelligent diagnostic & real-time monitoring system: Provides round-the-clock oversight of key components and operational parameters, alerting users to potential issues in advance for reliable, hassle-free operation. • Maintenance-friendly design & transport-optimized structure: Features easily accessible service points and a compact footprint, minimizing maintenance downtime and simplifying long-distance transportation.