All Terrain Lawn Mower

Product Introduction

Advantages and Features of Smartiger Multi function lawn mowre

Comprehensive Safety Protection MechanismsThe mower is integrated with a multi-layer safety system to safeguard both equipment and operators. Key safety features include a one-touch emergency stop switch, automatic over-slope warning (horn + light) and shut-off (alarm triggered at 50°, machine shut-off at 55°), LED headlamps for low-light working conditions, and automatic shut-off in case of signal loss or abnormal hydraulic oil and lube pressure. These functions effectively mitigate operational risks and ensure safe operation in complex environments. Versatile Attachment CompatibilityThe mower supports three types of professional attachments, meeting diverse vegetation management needs: ◦ Standard Flail Head: With a 1400mm rotor width, 3000rpm rotor speed, and 84L/min oil flow at 250bar pressure, it efficiently cuts grass and light wood up to 30mm in diameter. The cutting height is adjustable from 30mm to 90mm (3 positions via roller adjustment) and can be lifted for higher cutting. Its auto-float capacity allows the head to follow ground contours within ±10°, ensuring uniform cutting quality. ◦ Mulcher: Boasting a 1200mm working width and 2500rpm rotor speed, it can process vegetation up to 100mm in diameter, reducing waste volume and promoting on-site decomposition. ◦ Branch Crusher: Weighing 260kg, it can crush branches up to 120mm in diameter. Its intelligent hydraulic flow allocation with the host ensures optimal power utilization and crushing efficiency. Optimal Dimensions and Weight DistributionWith an overall width of 1500mm/2900mm (with flail mower) and height of 1300mm, the mower balances manoeuvrability and working coverage. The main unit weighs 1250kg, and the mulcher attachment weighs 380kg, ensuring stable grounding pressure on slopes and preventing slippage during operation.

Product Details

High-Speed Remote Control Multi-Function Slope Mowing Robot: Professional Solution for Challenging Terrain Maintenance

Our High-Speed Remote Control Multi-Function Slope Mowing Robot is specifically engineered to tackle the complexities of expansive green space maintenance and rugged terrain operations. As a professional-grade solution tailored for international B2B clients, it integrates high-velocity mowing performance, superior slope-adaptive capabilities, and versatile functional modules. This robot redefines operational efficiency and safety in terrain maintenance, making it an indispensable asset for professional landscaping firms, municipal greening departments, and industrial vegetation management projects worldwide.

As a high-speed slope mowing robot, it boasts an exceptional working efficiency of thousands of square meters per hour, perfectly suited for expansive green spaces including golf courses, large-scale municipal parks, and industrial campuses. The core advantage lies in its tracked undercarriage equipped with heightened teeth rubber tracks, which ensures outstanding ground adhesion and stable operation on uneven, challenging terrains—effectively eliminating slippage risks even in muddy or rocky areas. Optimized for 60° steep and rugged slopes, the robot features a robust anti-tipping design that guarantees safe and precise operation in extreme slope scenarios, complemented by intelligent safety mechanisms: automatic alarm activation at 50° and emergency shut-off at 55° to prevent potential hazards.

Technical Parameters

Model | Smartiger | |

ENGINE | ||

Maker | YANMAR 3-cylinder(European III emission standard) | |

Type | 4-cycle, Inline, Water-cooled Diesel | |

Fuel tank capacity | 28 litres | |

Gross output | 28.2Kw (38.3Hp) @2600rpm | |

Self-cleaning(optional) | Standard manual and automatic (optional) | |

HYDRAULICS | ||

Pumps | 3-tandem piston pump + 2 gear pump | (Bondioli & Pavesi) |

Driving motors | High torque motor | (Poclain) |

Flail mower motor | High speed motor | (Danfoss) |

Independent flail head circuit | Closed circuit piston | |

Independent track drive circuit | 2x closed circuit piston | |

Independent motions circuit | Opend circuit gear | |

TRACKS | ||

Rubber | Hieghtened teeth rubber track (max working angle 55°) | |

REMOTE CONTROL | ||

Working range | >150m | |

Frequency | 2.4G | |

Battery | Interchageable, rechargeable | |

Two with each unit charge on machine | ||

Propotional Joysticks | Standard | |

DIMENSIONS | ||

Overall width (with flail mower) | 1500mm | |

Overall width (with flail mower) | 2900mm | |

Overall height (with flail mower) | 1300mm | |

WEIGHT | ||

Smartiger | 1250Kg | |

Mulcher attachment | 380kgs | |

PERFORMANCE | ||

Gradient | Working on slopes up to 55° in any direction | |

(alarm at 50° and automatic shut-off at 55°) | ||

Potentiometer speed | 1st gear (low range) |

control (0 to 100%) | Forward and backward 0-4 Km/h |

2nd gear (high range) | |

Forward and backward 0-10.2 Km/h | |

Parking | Yes |

Steering | Skid-steering (support pivot-steering) |

Travelling bias correction | Yes |

Cruise Control System | Yes(One click release) |

PROTECTION AND SAFETY | |

Emergency stop | One-touch shut-off switch |

Over-slope | Automatic waring (Horn+Light) and shut-off |

Headlamp | LED |

Signal loss | Automatic shut-off |

Others | Automatic shut-off if hydraulic oil and lube |

pressure abnomaly | |

ATTACHMENT / FLAIL HEAD (STANDARD) | |

Standard attachment | Flail head |

Oil flow | 84L/min |

Pressure | 250bar |

Rotor speed | 3000rpm |

Front and rear flap | Chain and rubber |

Flails | Y-Flails for grass cutting and light wood |

up to 30mm diameter | |

Rotor width | 1400mm |

Rotor diameter | Grass and shrubs ≤30mm |

Cutting height range | 30mm-90mm (3 positions) |

(via roller adjustment) | flail can be lifted to cut higher than 90mm |

Hydraulic lift | -200mm to 500mm |

Auto-float capacity | Yes (follow ground contour up-down 10°) |

ATTACHMENT / MULCHER | |

Oil flow | 84L/min |

Pressure | 250bar |

Rotor speed | 2500rpm |

Front and rear flap | Chain |

Mulcher width | 1200mm |

Mulcher diameter | ≤100mm |

ATTACHMENT/BRANCH CRUSHER | |

Weight | 260kg |

Max.crushing diameter | 120mm |

Dimensions | 1800 * 90 * 1300mm |

Output power | intelligently allocated hydraulic flow with the host |

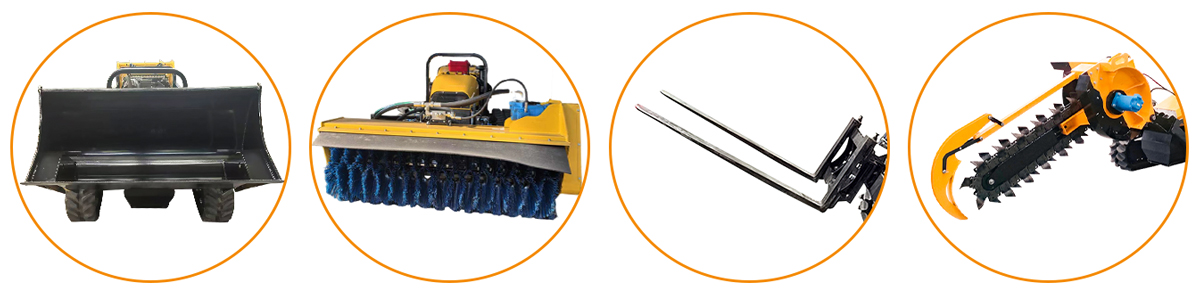

Optional Attachments

Application Scenarios

The New Remote Controlled Flail Mower: Application Scenarios

The New Remote Controlled Flail Mower, integrated with advanced power systems, superior terrain-adaptive structures and multi-functional operation modules, is specifically engineered to address the pain points of vegetation maintenance in complex and high-risk environments. Leveraging its core parameters such as strong slope-climbing capability, stable tracked operation, and remote control functionality, this professional-grade equipment has been widely recognized in global B2B markets, serving a diverse range of professional vegetation management scenarios that demand high efficiency, safety and precision. Its detailed application scenarios are as follows:

1. Highway and Railway Slope Greening Maintenance

Highway and railway slopes typically feature steep gradients (up to 55°) and uneven terrain, with traditional manual maintenance facing high safety risks and low efficiency. The New Remote Controlled Flail Mower is equipped with heightened teeth rubber tracks, enabling stable operation on slopes up to 55° in any direction (with automatic alarm at 50° and shut-off at 55° for safety). Its 2.4G remote control system with a working range exceeding 150m allows operators to conduct mowing operations from a safe distance, avoiding potential hazards such as slope collapse. The standard Y-flail head, capable of cutting grass and light wood up to 30mm in diameter, and the optional mulcher attachment for processing vegetation up to 100mm, perfectly meet the maintenance needs of slope green belts, ensuring the stability of slope vegetation and preventing soil erosion. Additionally, the mower’s compact dimensions (overall width 1500-2900mm, height 1300mm) enable it to operate flexibly in the narrow space between slope guardrails and roadways.

2. Golf Course and Large-Scale Landscape Green Space Maintenance

Golf courses, municipal parks, and large residential community green spaces require consistent and high-quality mowing results, while covering expansive areas. The New Remote Controlled Flail Mower boasts a high working efficiency of thousands of square meters per hour, supported by a 28.2Kw (38.3Hp) YANMAR diesel engine and a high-performance hydraulic system (84L/min oil flow, 3000rpm rotor speed). Its auto-float capacity allows the flail head to follow ground contours within ±10°, ensuring uniform cutting height (adjustable from 30mm to 90mm) even on undulating terrain. The skid-steering system with pivot-steering support enables flexible manoeuvring around landscape facilities, flower beds and water features. Moreover, the cruise control function (one-click release) reduces operator fatigue during long-hour continuous operation, significantly improving maintenance efficiency for large-area green spaces.

Packaging & Shipping

The New Remote Controlled Flail Mower: Professional Multi-Layer Packaging for Safe International Shipment

To ensure The New Remote Controlled Flail Mower—a high-precision all-terrain vegetation management equipment—reaches global B2B clients in intact physical condition and full operational readiness, we have developed a tailored, multi-tiered professional packaging system. This solution is specifically engineered to address the transit risks associated with the mower’s structural features (such as its 1250Kg main unit weight, rubber tracks, and precision hydraulic components) and long-distance international shipping demands, effectively safeguarding the equipment from potential damages. The detailed packaging procedures are as follows:

1. Industrial-Grade Hermetic Dustproof & Moisture-Proof Wrapping

The entire body of The New Remote Controlled Flail Mower, including its flail head attachment, rubber tracks, and remote control components, is fully wrapped with high-strength transparent industrial plastic film through a heat-shrinking process. This hermetic wrapping forms a reliable barrier against dust, humid air, and salt fog during ocean transportation, while also preventing minor scratches and abrasions on the equipment’s surface (such as LED headlamps and hydraulic interfaces) caused by handling operations.

2. Heavy-Duty Standardized Pallet Mounting

After the initial wrapping, the mower is securely fastened to reinforced wooden pallets that comply with ISPM 15 international shipping standards. The pallets are designed to bear the total weight of the mower (1250Kg for the main unit and 380Kg for the optional mulcher attachment) and are equipped with anti-slip rubber pads and metal fasteners to avoid any displacement during loading, unloading, and transit. This design enables efficient and safe handling via forklifts or pallet trucks at ports, warehouses, and job sites, significantly reducing the risk of accidental damage during transfer.

Company Profile

About Qingdao Huaying Intelligent Equipment Co., Ltd.

Qingdao Huaying Intelligent Equipment Co., Ltd., an affiliate of Shandong Hongchuan Machinery, specializes in the research and development, manufacturing, and global distribution of small to medium-sized intelligent engineering equipment. Our core product portfolio encompasses remote control all-terrain lawn mowers and high-performance slope mowers—two flagship offerings tailored for professional terrain maintenance scenarios.

Headquartered in Jining, China, we are dedicated to providing efficient, operator-friendly equipment solutions for a diverse range of industries, including professional landscaping, highway and railway slope greening maintenance, orchard management, and water conservancy project vegetation care. Our slope mowers, boasting exceptional 55° all-directional slope-climbing capability and stable rubber-tracked operation, stand out as core solutions for tackling challenging sloped terrain maintenance tasks that traditional equipment struggles to address.

Supported by a robust technical R&D team and a steadfast commitment to technological innovation, we prioritize the integration of advanced functionalities into our equipment. Both our remote control all-terrain lawn mowers and slope mowers are equipped with reliable remote control systems (over 150m working range) and comprehensive safety protection mechanisms, ensuring operational safety and precision. By delivering durable, adaptable, and high-performance machinery, we empower global B2B clients to effectively overcome real-world maintenance challenges, enhance operational efficiency, and reduce safety risks.

Why Choose Us?

Qingdao Huaying Intelligent Equipment: High-Performance Terrain Maintenance Solutions

At Qingdao Huaying Intelligent Equipment, we integrate profound industry experience with advanced engineering technologies to develop and supply high-caliber terrain maintenance machinery. Our product lineup covers the Remote Forestry Mulcher (featuring dual functions as a wireless remote-controlled mower), specialized Slope Mower, and high-performance All Terrain Lawn Mower. All our equipment adopts full remote-control operation, which not only maximizes operational safety by keeping operators away from hazardous work areas but also boosts work efficiency, making them well-suited for tackling rugged terrain, steep slopes, and intensive maintenance tasks.

Supported by rigorous manufacturing processes, continuous technological innovation, and in-depth on-site operational insights, our comprehensive product range delivers exceptional performance and reliability. Key advantages of these machines, including the All Terrain Lawn Mower, are as follows:

Dual-channel safety protection + intelligent automatic shutdown: Equipped with multi-layer safety mechanisms, such as over-slope alarm (triggered at 50°) and automatic shutdown (activated at 55°), ensuring secure operation on sloped terrain;

Superior all-terrain adaptability: The All Terrain Lawn Mower is fitted with heightened teeth rubber tracks (max working angle 55° in any direction) for stable movement on uneven ground; the Remote Forestry Mulcher is equipped with high-performance tungsten blades for efficient land clearing, while the Slope Mower is precision-engineered for steep gradient operations;

Flexible attachment interchangeability: Designed with quick-connect attachment interfaces, enabling swift replacement of functional modules to meet diverse needs such as mowing, mulching, and branch crushing;