Remote control forestry lawn mower

The heavy-duty tracked machinery (for multi-scenario operations) and Remote Mower On Tracks (for tracked vegetation management) share core high-performance features:

Multi-Functional Capability: Heavy-duty model handles land reclamation, mulching, mowing, snow clearing, rescue, and towing; Remote Mower On Tracks excels at tracked mowing/vegetation control.

Product Introduction

Tackle tough terrains effortlessly with the remote-controlled forestry mulcher and Remote Mower On Tracks:

Remote-Controlled Forestry Mulcher: Powered by a 53.7 kW Yanmar engine, it operates safely on ≤55° slopes, mulches ≤150 mm vegetation, has a 1500 mm cutting width, and a retractable, side-shift chassis for versatility—ideal for forests, grasslands, roadsides, embankments.

Remote Mower On Tracks: Complements with tracked stability, excelling at vegetation management in areas where conventional equipment struggles.

Both deliver unmatched performance for land clearing, hazard mitigation, and municipal maintenance.

Product Details

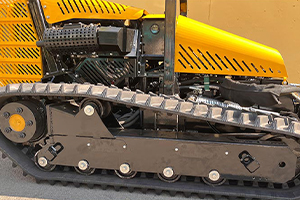

Power transmission: Moving fluid from pumps to motors or cylinders to generate motion. Control precision: Enabling smooth operation of attachments like mulching heads, lifting arms, | Equipped with rugged rubber tracks with reinforced anti-slip patterns, providing superior traction and stable movement across challenging terrain. | ||

Dual-flow fan with built-in cooling maintains ideal operating temperatures while automatically expelling dust and debris. | The mulching head is fully remote-operated, offering continuous speed control and smooth forward/reverse rotation. |

Proportional Joystick:

Key Features of Forestry Mower & Forestry Mower Cost

1. Core Controls & Maneuvering

Directional & Joystick Control: Joystick-based direction switching (front/rear leading) + knob-toggle forward/reverse; no U-turns needed.

In-Place Steering: Dual joysticks enable in-place turning and precision maneuvering in confined spaces.

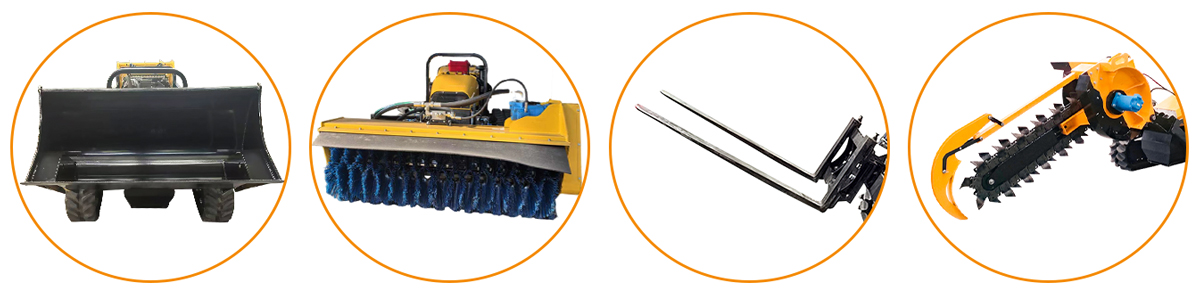

Quick Attachment Swap: <10-minute swaps via imported quick connectors (boosts efficiency, extends service life).

2. Remote Control & Safety

Full Remote Functionality: Controls engine start/stop, speed, lights, horn, and operations; 2-layer safety: built-in emergency stop, auto shutdown if no signal in 2s.

Safety Protection: 1-key emergency stop; auto alarm/shutdown for excessive tilt (50° alert, 55° shutdown), signal loss, abnormal hydraulic/lubricating oil pressure.

Technical Parameters

Parameter | Specification | Parameter | Specification |

Model | HYZH-40 | Pressure | 250bar |

Engine Brand | Changchai | Headlight | LED |

Fuel | Diesel | Tool Rotation Speed | 2500rpm |

Fuel Tank Capacity | 28L | Tool Rotation Direction | Forward/Reverse (Bi-directional 0-100% stepless adjustable) |

Torque | 105.5Nm | Attachment Front Cover Control | Remote control |

Fuel Injection Method | Direct injection | Tool Material | Tungsten steel |

Rated Power | 35Kw | Working Width | 1200mm |

Transmission System | Hydrostatic precision control | Number of Tools | 27 pieces |

Cooling System | Oil-air hybrid cooling | Crushing Diameter | 100mm |

Vertical Obstacle Height | 500mm | Forearm Lifting Range | -200mm to +500mm |

Wading Depth | 500mm | Slope Capacity | Suitable for 55° slope operation |

Departure Angle | 30° | Dimensions | 3230mm × 1450mm × 1420mm |

Straight-line Deviation | 0.3% | Machine Weight | 1840kg |

Topsoil Turning Depth | 20mm | Ground Clearance | 170mm |

Remote Control Range | >150m | Terrain Adaptability | Yes (adapts to ±10° terrain undulation) |

Allowed Tilt Angle | 60° in any direction (after engine optimization) | Steering System | Skid steering, supporting in-place turning |

Hydraulic Pump | Piston pump + Gear pump | Allowed System Tilt | ≥80° in any direction (after hydraulic system optimization) |

Drive Motor | High-torque motor | Speed Control | Working speed: 0-4 km/h (forward/reverse); Transfer speed: 0-10.2 km/h (forward/reverse) |

Hydraulic Tank Capacity | 26L (40L total system capacity) | Parking System | Remote-controlled parking brake |

Hydraulic Flow Rate | 84L/min | Track Type (Standard) | High-tooth rubber track (suitable for 55° slope operation). The tooth height of the special working condition rubber track is twice that of ordinary/common tracks on the market, achieving strong grip, friction, and adaptability to various terrains |

Frequency | 2.4G | Battery | 2 built-in rechargeable lithium batteries per unit, supporting self-charging |

Optional Attachments

Application Scenarios

The Reclamation Robot and Remote Tools Carrier are versatile equipment for multi-scenario operations:

Reclamation Robot

It consists of two main components: a fully hydraulic power platform and front/rear working attachments. Optional functional modules include reclamation, crushing, mowing, deicing/snow removal, emergency engineering rescue, and a towing winch. This flexible configuration allows it to handle diverse disaster response and accident recovery tasks, boosting operational efficiency and machine utilization.

Remote Tools Carrier

As a complementary equipment, it supports remote-controlled transportation and deployment of various working tools/attachments. It works in tandem with the reclamation robot (or independently) to enhance tool mobility, ensuring quick access to required modules for disaster response, recovery, or routine operations—further elevating overall work efficiency.

Packaging & Shipping

Secure Packaging for the Remote Forestry Mulcher

To ensure each Remote Forestry Mulcher arrives in perfect condition, we implement a comprehensive and robust packaging process:

Dustproof & Moisture-Resistant Wrapping

Each unit is tightly wrapped in transparent plastic film, protecting it from dust, moisture, and minor abrasions during transit.

Palletized Base for Efficient Handling

The mulcher is mounted on a sturdy wooden pallet, allowing safe, smooth, and convenient loading, unloading, and forklift operations at ports or job sites.

Reinforced Wooden Crates for Maximum Protection

For long-distance or international shipments, the palletized mulcher is enclosed in heavy-duty wooden crates, offering superior resistance against impacts, compression, and other shipping hazards.

This multi-layered packaging ensures every machine arrives fully protected, intact, and ready for immediate operation.

Company Profile

Qingdao Huaying Intelligent Equipment Co., Ltd., a subsidiary of Shandong Hongchuan Machinery, is dedicated to the research, development, manufacturing, and sales of small to medium-sized intelligent machinery. Headquartered in Jining, China, we provide efficient and easy-to-use solutions for landscaping, road maintenance, orchard management, and other applications. With strong technical capabilities and a focus on innovation, we deliver dependable, versatile equipment that helps customers address practical challenges with confidence and efficiency.

Why Choose Us?

At Qingdao Huaying Intelligent Equipment, we blend deep industry know-how with advanced engineering to create machines that excel in the toughest conditions. The Remote Forestry Mulcher is purpose-built to conquer rugged terrain, steep slopes, and heavy-duty vegetation work—delivering full remote-controlled operation for superior safety, precision, and efficiency.

Driven by our commitment to reliable manufacturing, continuous innovation, and real-world performance, we bring you:

Dual safety systems with automatic shutdown for secure operation on any gradient.

High-efficiency tungsten blade mulching for exceptional cutting power and terrain adaptability.

Quick-change attachment system to switch tools effortlessly for different tasks.

Smart diagnostics with real-time monitoring for confident, trouble-free operation.

Maintenance-friendly, transport-ready design to keep downtime to a minimum.

From land clearing and vegetation control to ecological restoration, our intelligent solutions are built to maximize productivity, minimize risks, and keep your operations moving forward.