Tracked Lawn Mower

Smartiger is a high-performance, remote-controlled tracked lawn mower and multi-function clearing robot. Designed specifically for complex terrains, it is particularly suitable for steep slopes, forestry clearing, and municipal landscaping maintenance.

Endurance: Equipped with a 28-liter fuel tank to ensure sustained operating capability.

Cleaning System: Features a standard manual self-cleaning system, with an optional automatic self-cleaning function available to adapt to dusty environments.

Product Details

Product Introduction

The Tracked Lawn Mower and Zero Turn Mower With Tracks (track-equipped for enhanced maneuverability) are high-performance vegetation management machines designed for challenging terrain and steep slopes.

Both feature:

Tilt sensors, over-angle alarms, and automatic shutdown (maximizing operational safety);

Advanced hydrostatic drive and slope correction (stable performance on inclines up to 55°);

Oil-water integrated cooling with reversible fan (efficient operation in harsh conditions);

Full remote control (easy operation of engine functions, lighting, horn, attachments);

Quick-change couplers, high-strength tungsten blades, and real-time monitoring (water/oil temperature, oil level, RPM, blockage).

The Tracked Lawn Mower excels in forestry, land clearing, and slope management; the Zero Turn Mower With Tracks adds superior agility for precise trimming in complex layouts. Both deliver efficient, reliable, and safe performance.

Product Details

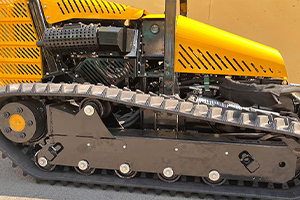

Built for peak performance in the toughest environments, this machine is mounted on heavy-duty rubber tracks with reinforced anti-slip treads, delivering exceptional traction and stable mobility across uneven, slippery, or challenging terrain. Its advanced thermal management system pairs a bidirectional fan with an integrated cooling circuit to consistently maintain optimal operating temperatures while automatically expelling dust and debris—ensuring reliable, uninterrupted operation even in dusty conditions. | ||

The mulching head offers full remote control with stepless speed adjustment and smooth bidirectional rotation, providing unmatched precision and versatility for a wide range of vegetation management tasks. Whether clearing dense undergrowth or performing fine mulching, operators can easily adapt the head’s speed and direction to match the material and terrain, enhancing efficiency and reducing downtime. |

Technical Parameters

Model | Smartiger | |

ENGINE | ||

Maker | YANMAR 3-cylinder(European III emission standard) | |

Type | 4-cycle, Inline, Water-cooled Diesel | |

Fuel tank capacity | 28 litres | |

Gross output | 28.2Kw (38.3Hp) @2600rpm | |

Self-cleaning(optional) | Standard manual and automatic (optional) | |

HYDRAULICS | ||

Pumps | 3-tandem piston pump + 2 gear pump | (Bondioli & Pavesi) |

Driving motors | High torque motor | (Poclain) |

Flail mower motor | High speed motor | (Danfoss) |

Independent flail head circuit | Closed circuit piston | |

Independent track drive circuit | 2x closed circuit piston | |

Independent motions circuit | Opend circuit gear | |

TRACKS | ||

Rubber | Hieghtened teeth rubber track (max working angle 55°) | |

REMOTE CONTROL | ||

Working range | >150m | |

Frequency | 2.4G | |

Battery | Interchageable, rechargeable | |

Two with each unit charge on machine | ||

Propotional Joysticks | Standard | |

DIMENSIONS | ||

Overall width (with flail mower) | 1500mm | |

Overall width (with flail mower) | 2900mm | |

Overall height (with flail mower) | 1300mm | |

WEIGHT | ||

Smartiger | 1250Kg | |

380kgs | ||

PERFORMANCE | ||

Gradient | Working on slopes up to 55° in any direction | |

(alarm at 50° and automatic shut-off at 55°) | ||

Potentiometer speed | 1st gear (low range) |

control (0 to 100%) | Forward and backward 0-4 Km/h |

2nd gear (high range) | |

Forward and backward 0-10.2 Km/h | |

Parking | Yes |

Steering | Skid-steering (support pivot-steering) |

Travelling bias correction | Yes |

Cruise Control System | Yes(One click release) |

PROTECTION AND SAFETY | |

Emergency stop | One-touch shut-off switch |

Over-slope | Automatic waring (Horn+Light) and shut-off |

Headlamp | LED |

Signal loss | Automatic shut-off |

Others | Automatic shut-off if hydraulic oil and lube |

pressure abnomaly | |

ATTACHMENT / FLAIL HEAD (STANDARD) | |

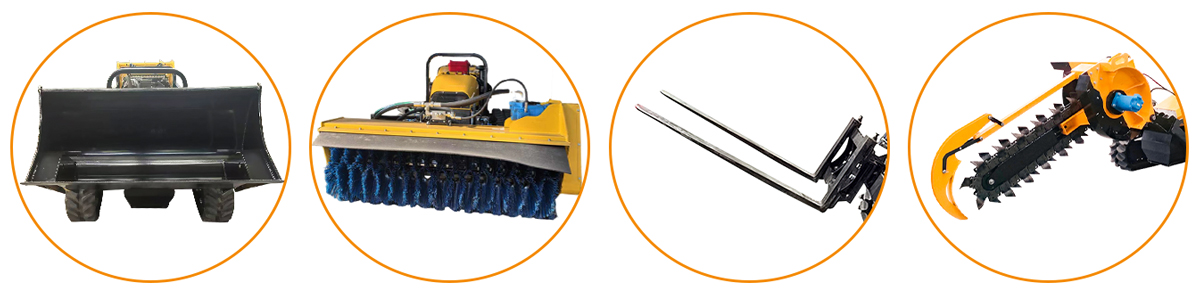

Standard attachment | Flail head |

Oil flow | 84L/min |

Pressure | 250bar |

Rotor speed | 3000rpm |

Front and rear flap | Chain and rubber |

Flails | Y-Flails for grass cutting and light wood |

up to 30mm diameter | |

Rotor width | 1400mm |

Rotor diameter | Grass and shrubs ≤30mm |

Cutting height range | 30mm-90mm (3 positions) |

(via roller adjustment) | flail can be lifted to cut higher than 90mm |

Hydraulic lift | -200mm to 500mm |

Auto-float capacity | Yes (follow ground contour up-down 10°) |

ATTACHMENT / MULCHER | |

Oil flow | 84L/min |

Pressure | 250bar |

Rotor speed | 2500rpm |

Front and rear flap | Chain |

Mulcher width | 1200mm |

Mulcher diameter | ≤100mm |

ATTACHMENT/BRANCH CRUSHER | |

Weight | 260kg |

Max.crushing diameter | 120mm |

Dimensions | 1800 * 90 * 1300mm |

Output power | intelligently allocated hydraulic flow with the host |

Optional Attachments

Application Scenarios

Excellent Steep Slope Capability and Anti-Slip Performance

High Traction: Heightened teeth rubber tracks (such as Smartiger's "Heightened teeth rubber track") grip grass and soil tightly, providing immense friction.

Extreme Angles: These machines are designed to operate on slopes up to 55°, equipped with tilt alarms and automatic shut-off functions to ensure safety on embankment slopes.

Low Center of Gravity: The tracked chassis typically features a lower center of gravity, significantly reducing the risk of tipping over.

Problem Solved: Water conservancy embankments often feature steep slopes (typically between 30° and 45°), where conventional wheeled equipment is prone to slipping or even rollovers.

Track Advantages:

Zero Turn Mower With Tracks Minimal Turning Radius and High Flexibility (Zero Turn Radius)

On-the-Spot Turning: By rotating the left and right tracks in opposite directions, the machine achieves a 0° turning radius. This allows it to turn around on the spot on narrow embankment tops or at the bottom of ditches without requiring wide turnaround space.

Precise Control: Paired with proportional remote control joysticks, operators can make micro-adjustments to the machine's position, easily clearing complex dead zones around bridge piers and near drainage outlets.

Problem Solved: Ditches are often narrow and winding, and access roads on top of embankments are limited, making it difficult for large equipment to turn around or reach dead corners.

Zero-Turn Advantages:

Low Ground Pressure and Minimal Surface Damage

Large Contact Area: Tracks distribute the machine's total weight (e.g., 1.6 tons) over a vast contact surface, resulting in extremely low ground pressure.

Vegetation Protection: While clearing weeds, the machine does not destroy the existing slope protection turf, which aids in soil and water conservation and aligns with the hydraulic engineering requirement of "slope protection and soil stabilization."

Problem Solved: The soil structure of embankments and ditches can be relatively soft (especially after rain). Heavy wheeled equipment can easily damage turf, leave deep ruts, or even compromise the embankment's anti-seepage layers.

Track Advantages:

Company Profile

As a prestigious subsidiary of Shandong Hongchuan Machinery, we are a leading enterprise specializing in R&D, manufacturing, and sales of small-to-medium-sized intelligent equipment—including the specialized Xtreme Slope Mower (for ultra-steep terrain mowing).

Headquartered in Jining (a city with profound industrial heritage and innovation), we deliver efficient, reliable, user-friendly machinery solutions for landscaping, road maintenance, orchard management, land clearing, and environmental governance.

Leveraging robust technical expertise, advanced manufacturing capabilities, and decades of industry experience, we develop equipment to solve real-world challenges—such as the Xtreme Slope Mower, engineered for safe, efficient operation on ultra-steep inclines. Committed to continuous innovation, all our products (including the Xtreme Slope Mower) integrate durability, adaptability, and intelligent functionality, empowering global clients to boost productivity, safety, and efficiency.

By fusing cutting-edge technology with practical engineering, we have become a trusted partner for those seeking intelligent, dependable equipment solutions.

Why Choose Us?

Q1: Our working environment is extremely hazardous, with slopes often exceeding 40°. It’s too dangerous for manual labor, and conventional machines can’t climb them. Can Smartiger solve this?

A: Absolutely. Smartiger is born for extreme terrains.

55° Extreme Climbing: Equipped with heightened teeth rubber tracks and a low-center-of-gravity chassis, it operates stably on slopes up to 55° (conventional wheeled equipment typically slips at around 25°).

Triple Safety Lock: When the slope reaches 50°, an audio-visual alarm automatically activates; once it hits the critical 55° limit, the machine automatically shuts down, completely eliminating the risk of rollovers.

Human-Machine Separation: Operators can control the machine remotely from a safe zone up to 150 meters away. Let the machine take the risks while keeping people out of harm’s way.

Q2: The space on top of embankments and inside ditches is very narrow. Large equipment can’t get in, but small equipment has low efficiency. What should we do?

A: Smartiger features "Zero Turn" black technology—agile as a snake, powerful as a tiger.

On-the-Spot U-Turn: Leveraging Zero Turn technology, the left and right tracks can rotate in opposite directions to achieve a 0° turning radius. It can turn around on the spot at the bottom of narrow ditches or on embankment roads without needing to reverse.

Precision Micro-Control: Equipped with proportional remote control joysticks, operators can adjust the machine's position with millimeter-level precision, easily clearing complex dead zones around bridge piers and drainage outlets.

Compact Body: With an overall width of only 1500mm, it unleashes a powerful 38.3 HP—small in size, huge in energy.

Q3: We are concerned that heavy machinery might damage the embankment turf or compromise the anti-seepage layers. Will Smartiger damage the ground?

A: No. Smartiger was designed with "slope protection and soil stabilization" in mind.

Ultra-Low Ground Pressure: Although the machine weighs 1.6 tons, its wide rubber tracks distribute the weight evenly, resulting in ground pressure far lower than that of wheeled equipment.

Vegetation Protection: Even when operating on soft soil after rain, it leaves no deep ruts and does not destroy the grass root layer, perfectly meeting the strict requirements for soil and water conservation in hydraulic engineering.

Terrain Following: The cutting head features a ±10° automatic floating function, allowing it to conform to uneven ground for cutting and avoiding hard scraping that could damage the soil layer.

Leave your messages