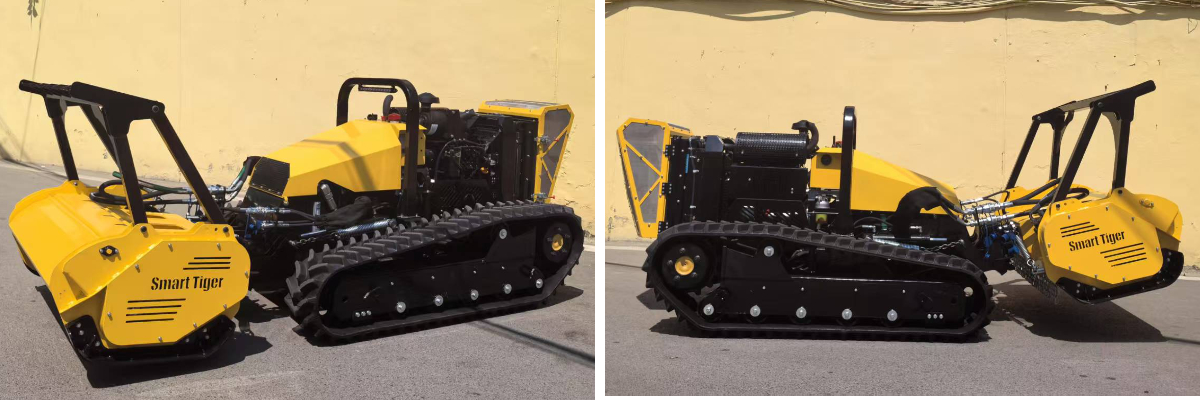

Diesel Remote Control Lawn Mower

The remote-controlled mower for hills and Professional Remote Controlled Tracked Carrier (both optimized for sloped terrain) offer core advantages:

Slope Adaptability: Remote-controlled mower for hills handles slopes up to 55° with advanced lubrication for smooth uneven-terrain performance; tracked carrier matches with slope-suited operation.

Superior Stability: Both have anti-slip tracks (remote mower adds reinforced oil pan) for reliable traction and steady work on steep inclines.

Product Introduction

The hydraulic remote-controlled mower for hills and Professional Remote Controlled Tracked Carrier are high-performance machines for steep/uneven terrain tasks:

Power & Control: Both rely on robust systems—hill mower uses YANMAR diesel engine + advanced hydraulic system (precise movement/cutting/track control); tracked carrier matches with reliable drive for terrain adaptability.

Slope Stability: Hill mower has reinforced high-tooth rubber tracks (traction/stability on ≤55° slopes); tracked carrier complements with terrain-suited design for steep-ground reliability.

Functionality: Hill mower handles grass, shrubs, 100mm branches (adjustable rotor speeds, interchangeable tools); tracked carrier supports heavy-duty transport/operation on rough slopes.

Safety & Range: Hill mower has full safety features + >150m remote range; tracked carrier also uses remote control for safe, distant operation.

Product Details

Equipped with high-quality hydraulic hoses from Continental (Germany) or Yokohama (Japan) for reliable performance and extended service life. | Fitted with heavy-duty rubber tracks featuring reinforced anti-slip patterns, providing excellent grip and steady mobility on diverse surfaces. | ||

The integrated dual-direction fan system ensures optimal temperature control and automatically removes dust for continuous, efficient operation. | Remote-operated mulching head with stepless speed control and seamless forward/reverse rotation switching. |

Technical Parameters

Parameter | Specification | Parameter | Specification |

Model | HYZH-40 | Pressure | 250bar |

Engine Brand | YANMAR | Headlight | LED |

Fuel | Diesel | Tool Rotation Speed | 2500rpm |

Fuel Tank Capacity | 28L | Tool Rotation Direction | Forward and reverse (bidirectional 0-100% stepless adjustable) |

Torque | 107.1Nm | Control of Attachment Front Cover Opening/Closing | Remote control |

Fuel Injection Method | Direct injection | Tool Material | Tungsten steel |

Rated Power | 28.2Kw | Working Width | 1200mm |

Transmission Mode | Hydrostatic precision control | Number of Tools | 27 |

Cooling Method | Oil-air hybrid cooling | Crushing Diameter | 100mm |

Vertical Obstacle Crossing Height | 500mm | Forearm Lifting Height | -200mm to 500mm |

Wading Depth | 500mm | Supported Slope | Meets working conditions with a slope angle of 55° |

Departure Angle | 30° | Dimensions | 3230mm × 1450mm × 1420mm |

Straight-line Deviation Angle | 0.3% | Self-weight | 1840kg |

Topsoil Backfilling Depth | 20mm | Maximum Traction Force | 25KN |

Working Distance of Remote Control System | >150m | Ground Clearance | 170mm |

Allowed Operating Inclination Angle | 60° in any direction (after engine optimization) | Attachment Terrain Matching | Yes (matches terrain undulations within ±10°) |

Hydraulic Pump | Piston pump + gear pump | Steering | Skid steering, supporting in-place steering |

Drive Motor | High-torque motor | System Allowed Operating Inclination Angle | ≥80° in any direction (after hydraulic system optimization) |

Hydraulic Tank Capacity | 26L (40L in the system) | Hydraulic Flow of Reclamation Attachment | 84L/min |

Stepless Speed Control | Working speed: forward/reverse 0-4 Km/h; Transfer speed: forward/reverse 0-10.2 Km/h | Parking Mode | Remote control. The parking switch ensures stable parking of the equipment. The parking knob enables on-site parking and electronic handbrake function, effectively ensuring safety, preventing sliding, and avoiding safety accidents caused by misoperation. |

Rubber Track (Standard) | High-tooth rubber track (supports 55° slope working conditions). Special working condition rubber track with teeth twice as high as ordinary/common tracks on the market, achieving strong grip, friction, and adaptability to various terrains | Proportional Joystick | Supports joystick direction switching for convenient operation when driving with the front or rear of the machine forward. Direction switching (forward/reverse) can be realized via the knob switch, which is more efficient without the need for U-turn. |

Frequency | 2.4G | Battery | 2 built-in rechargeable lithium batteries per unit, supporting self-charging |

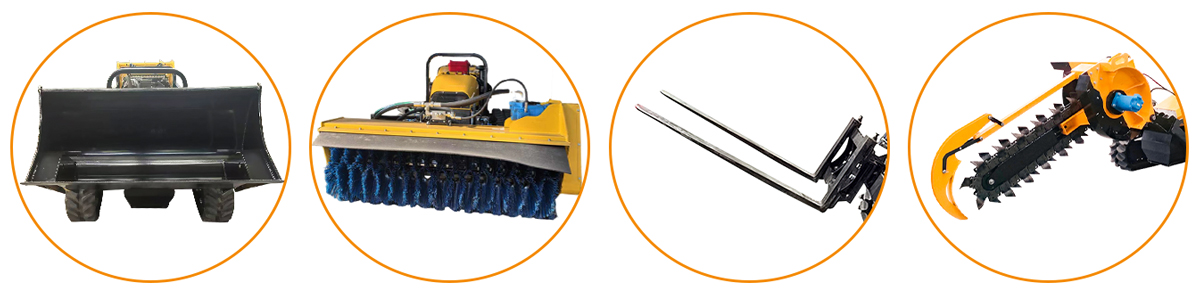

Optional Attachments

Application Scenarios

The remote-controlled mower for hills and Remote-Controlled Forestry Grass Shredder excel in vegetation management across key scenarios:

Urban Greening: Remote-controlled mower for hills manages vegetation in parks, greenways, and roadside slopes (ideal for inclined urban landscapes).

River & Flood Dike Maintenance: Both machines clear embankment vegetation to boost slope stability and support flood protection.

Highway & Railway Slope Management: Safely trim vegetation along steep transport corridors (highways/railways) via remote operation.

Agricultural Slope Maintenance: Remote-controlled mower for hills handles farmland/orchard edge weeds/grass without crop damage.

Mountain & Forest Land Management: Remote-Controlled Forestry Grass Shredder excels at grass cutting and land reclamation in rugged mountain/forest areas; hill mower complements for sloped-terrain tasks.

Power Line & Hazard Zone Control: Both enable safe vegetation management in restricted/hazardous sloped zones, keeping operators at a safe distance.

Packaging & Shipping

To guarantee the remote-controlled mower for hills and High Grass Rotary Mulcher reach destinations in pristine condition, we implement a meticulous multi-layered packaging process:

Dust & Moisture Protection: Each unit is securely wrapped in transparent protective film, shielding from dust, moisture, and minor transit abrasions.

Palletized Base: Units are mounted on robust wooden pallets for safe forklift handling and smooth loading/unloading at ports, warehouses, or job sites.

Reinforced Crates: For long-distance/overseas shipments, palletized machines are enclosed in heavy-duty wooden crates to resist impacts, compression, and transport stresses.

This thorough approach ensures both models arrive fully protected, damage-free, and ready for immediate operation.

Company Profile

Qingdao Huaying Intelligent Equipment Co., Ltd., a subsidiary of Shandong Hongchuan Machinery Manufacturing Co., Ltd., focuses on R&D, production, and sales of small-to-medium-sized intelligent machinery—with the remote controlled mower for hills as a key offering.

Leveraging strong technical capabilities and a robust regional industrial base, we provide efficient, versatile, easy-to-use solutions (including the remote controlled mower for hills) for gardens, roads, orchards, and sloped-terrain applications.

Committed to quality and innovation, our equipment (such as the remote controlled mower for hills) is designed to boost productivity, support sustainability, and deliver reliable performance in real-world operations.

Why Choose Us?

At Qingdao Huaying Intelligent Equipment, we blend deep industry expertise and advanced engineering to design field-ready machines—including the Remote Forestry Mulcher, remote controlled mower for hills, High Grass Rotary Mulcher, and Orchard remote-controlled lawn mower. The mulcher suits rugged/steep terrain; the hill mower excels at safe hilly vegetation management; the rotary mulcher handles high-grass processing; the orchard lawn mower specializes in precise orchard vegetation care—all prioritize performance and safety.

Backed by reliable manufacturing, continuous innovation, and field insight, our equipment delivers:

Dual safety systems + automatic shutdown for stable operation on extreme inclines;

Targeted efficiency: mulching (forestry mulcher), hill cutting (hill mower), high-grass processing (rotary mulcher), orchard trimming (orchard lawn mower)—all with strong landscape adaptability;

Quick tool-free attachment changes to avoid workflow interruptions;

Smart diagnostics + real-time monitoring for hassle-free use;

Low-maintenance, transport-ready design to minimize downtime.